In industries where hazardous materials are handled, safety is paramount. One of the critical components used to ensure secure operations in such environments is the explosion-proof electric butterfly valve. These valves are specially designed to prevent the ignition of hazardous gases or chemicals during operation, protecting both the personnel and equipment in areas prone to explosions. As a result, the demand for high-quality explosion-proof electric butterfly valves has risen significantly in recent years. Manufacturers who specialize in these valves play a vital role in improving safety and operational efficiency in a wide range of industries, from oil and gas to chemical processing.

What Is an Explosion-Proof Electric Butterfly Valve?

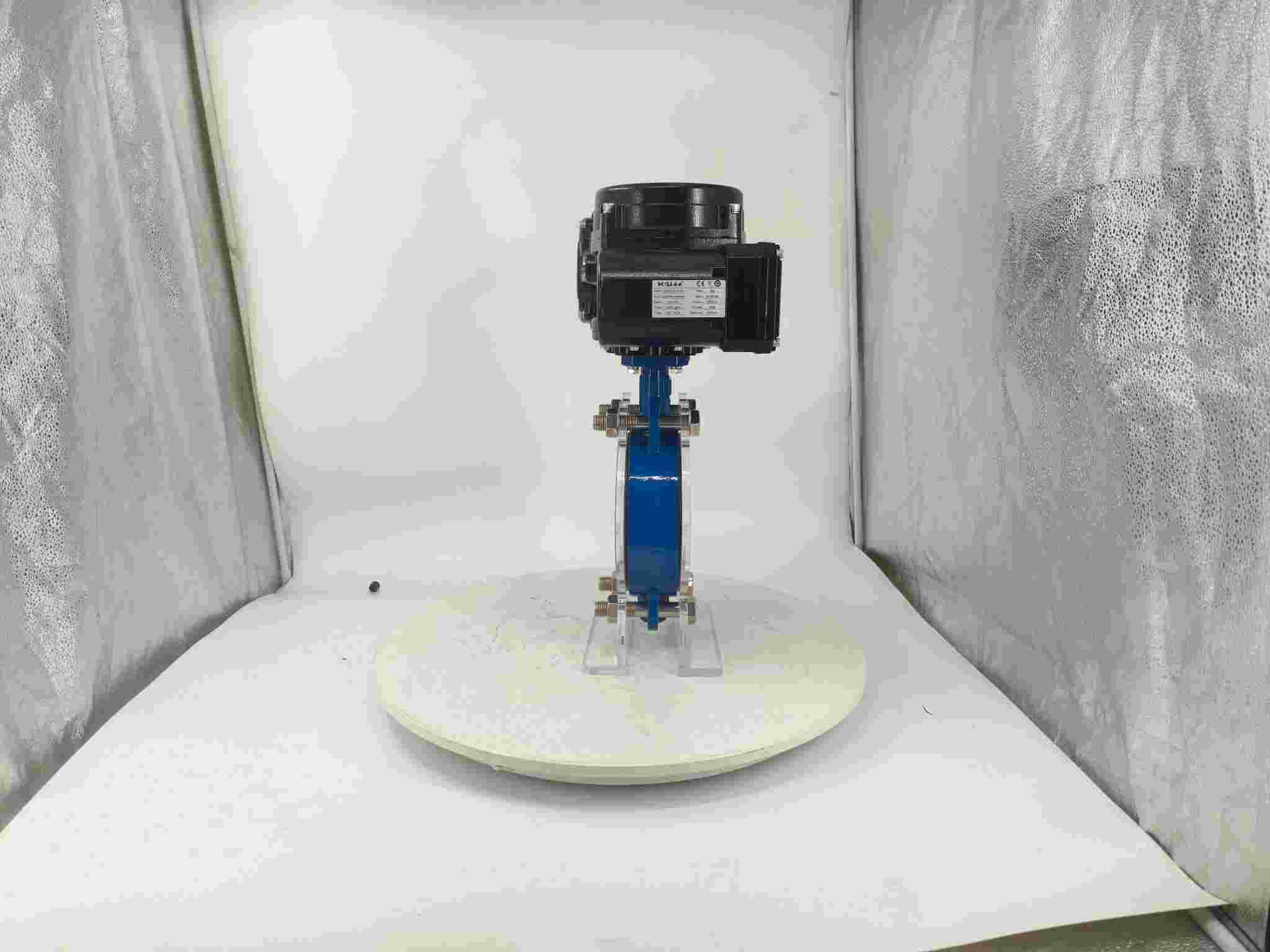

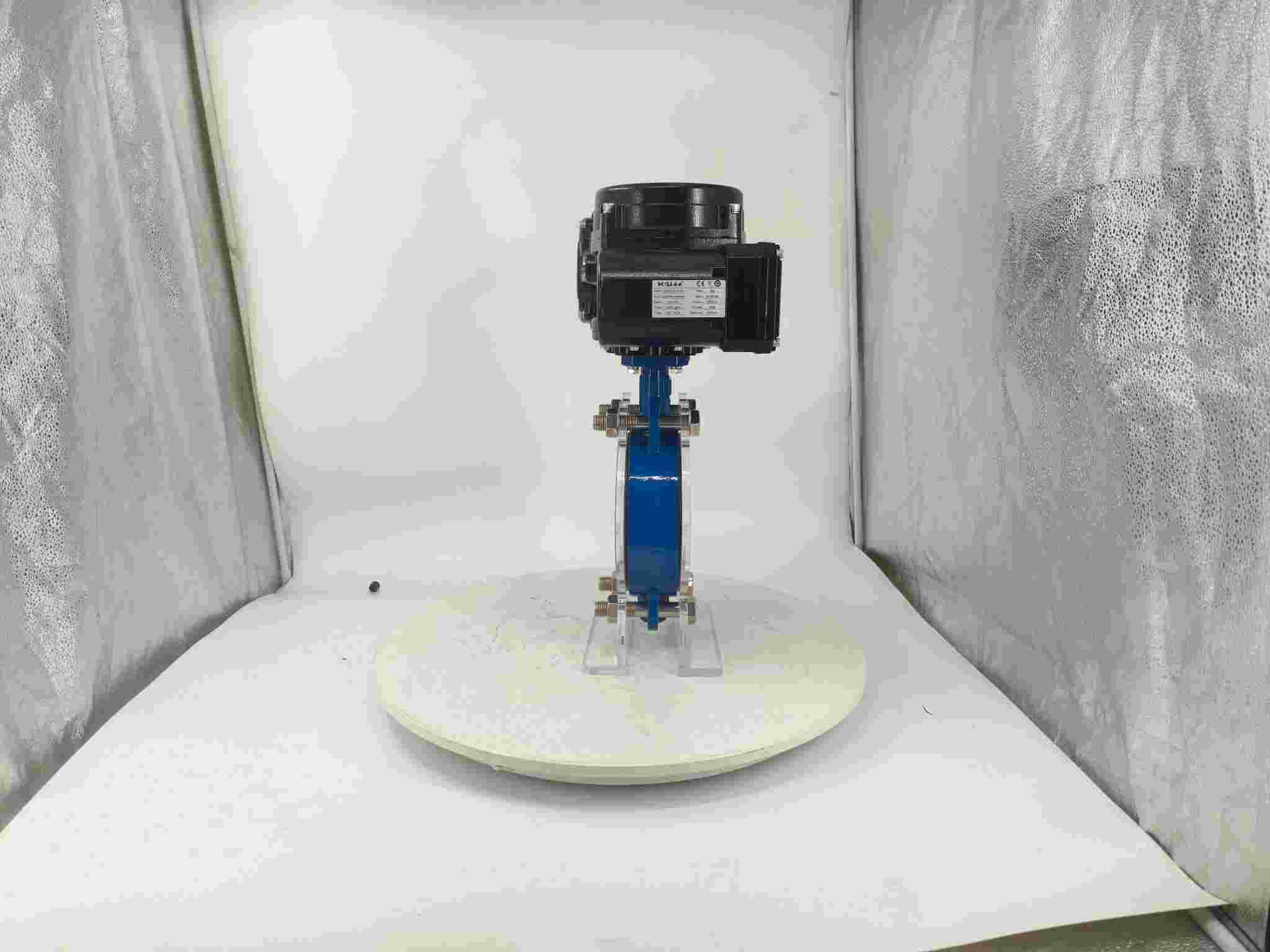

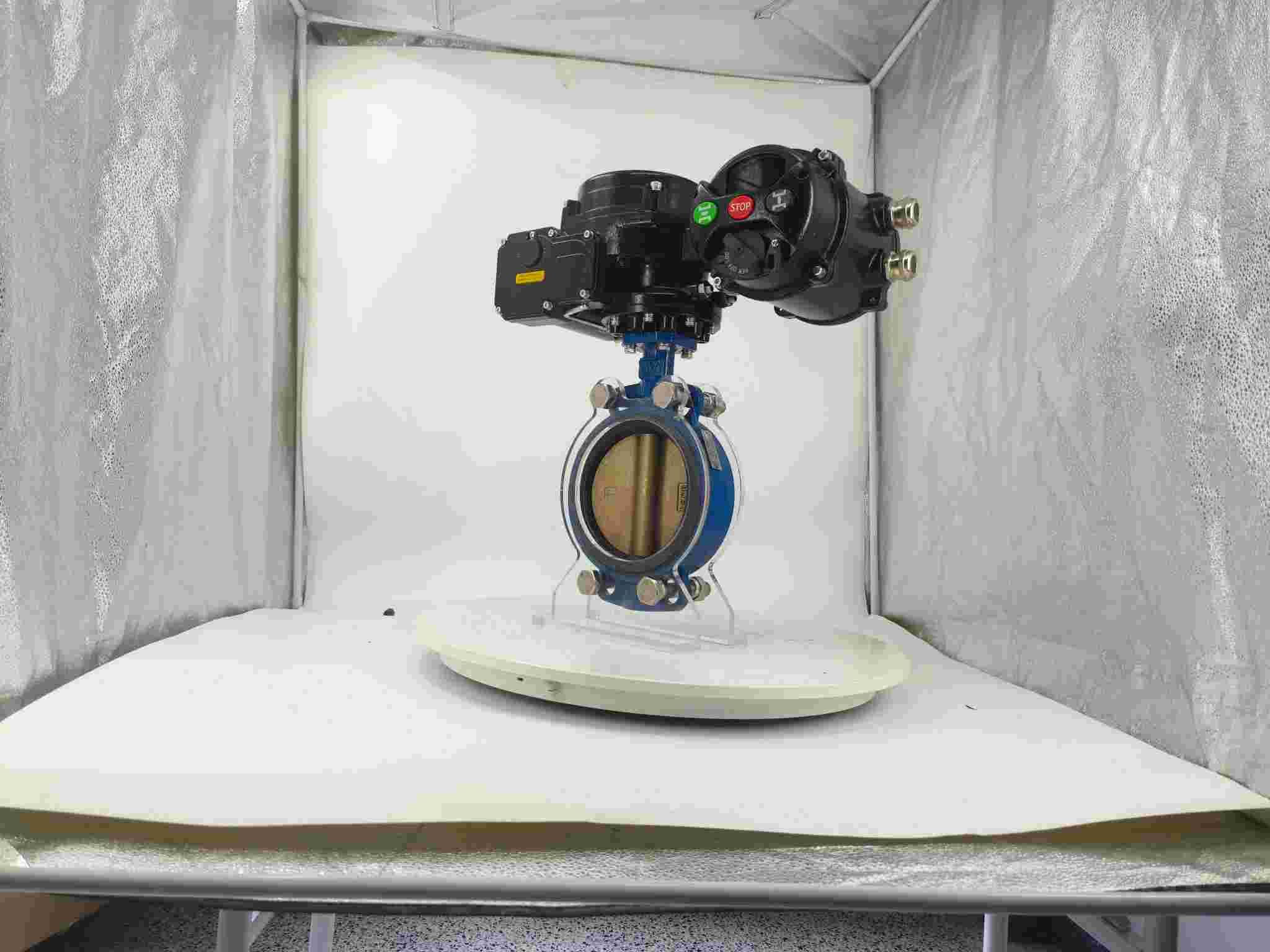

An explosion-proof electric butterfly valve is a valve equipped with a motorized actuator that is designed to control the flow of fluids or gases in an explosion-risk environment. The valve’s body, as well as the actuator, is designed and manufactured to meet strict safety standards. These valves use an electric actuator, which can be remotely controlled, to adjust the flow of material through the pipeline. The explosion-proof nature of the valve ensures that any potential spark or electrical fault within the valve or actuator does not cause ignition, even in the presence of flammable gases, vapors, or dust.