Electric bellows stop valves are essential components in modern fluid control systems, offering precision and reliability in the regulation of flow within pipes and channels. These valves are particularly useful in systems where leakage control, minimal pressure drops, and tight shutoff are crucial. With the rising demands for automation in industries such as oil and gas, water treatment, and chemical processing, the role of electric bellows stop valves becomes even more critical. In this article, we explore the design, function, and applications of electric bellows stop valves, with a special focus on the role of collaborative automation in enhancing their performance and efficiency.

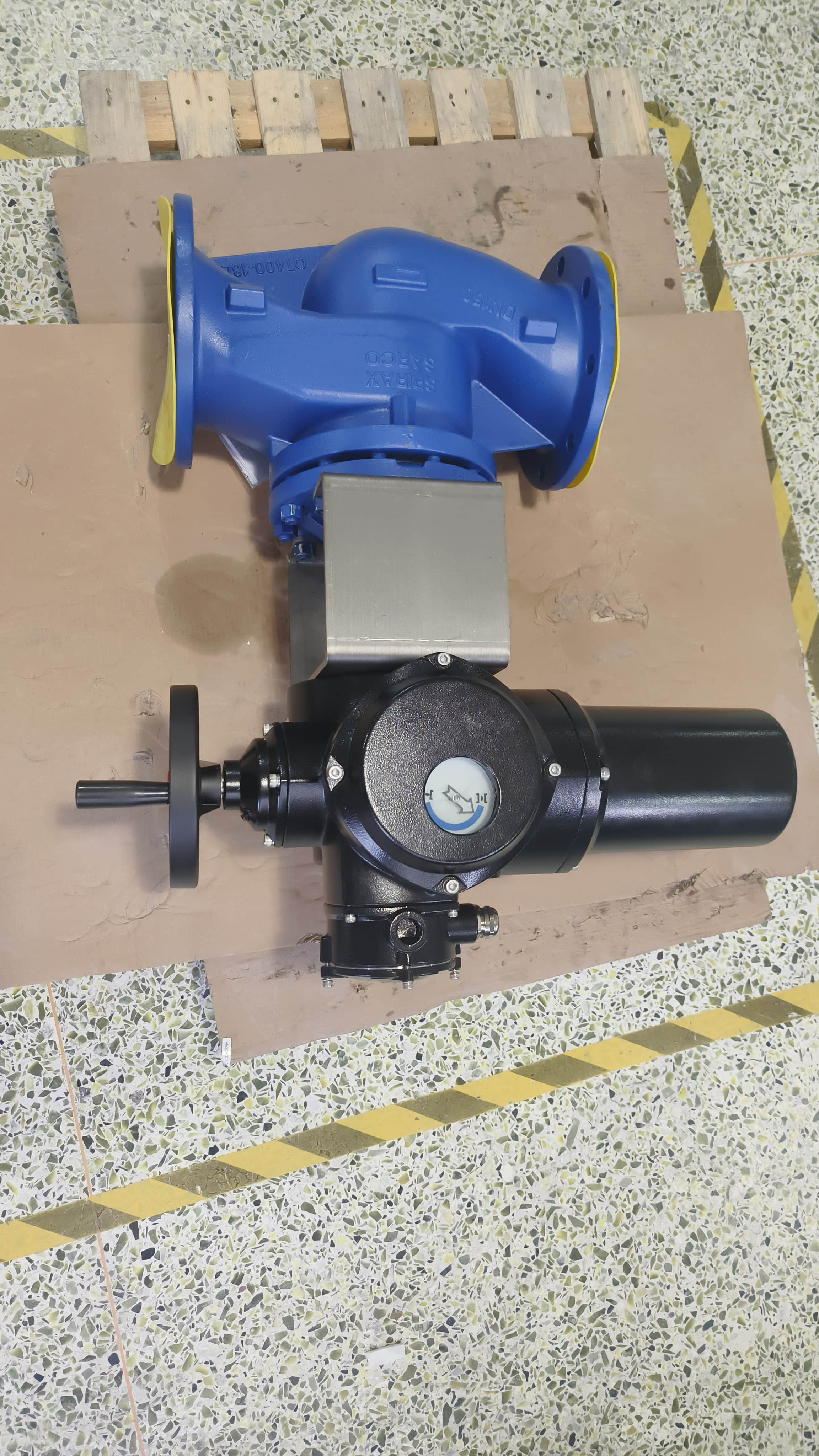

Understanding Electric Bellows Stop Valves