understanding pneumatic ball valves: mechanisms, applications, and advantages

Release time:2024-10-15 23:24:22

Pneumatic ball valves are essential components in many industrial applications, providing reliable and efficient control of fluid flow. Utilizing compressed air to actuate their mechanisms, these valves offer numerous advantages, making them a preferred choice in various systems. This article delves into the workings of pneumatic ball valves, their applications, and the benefits they offer to industries.

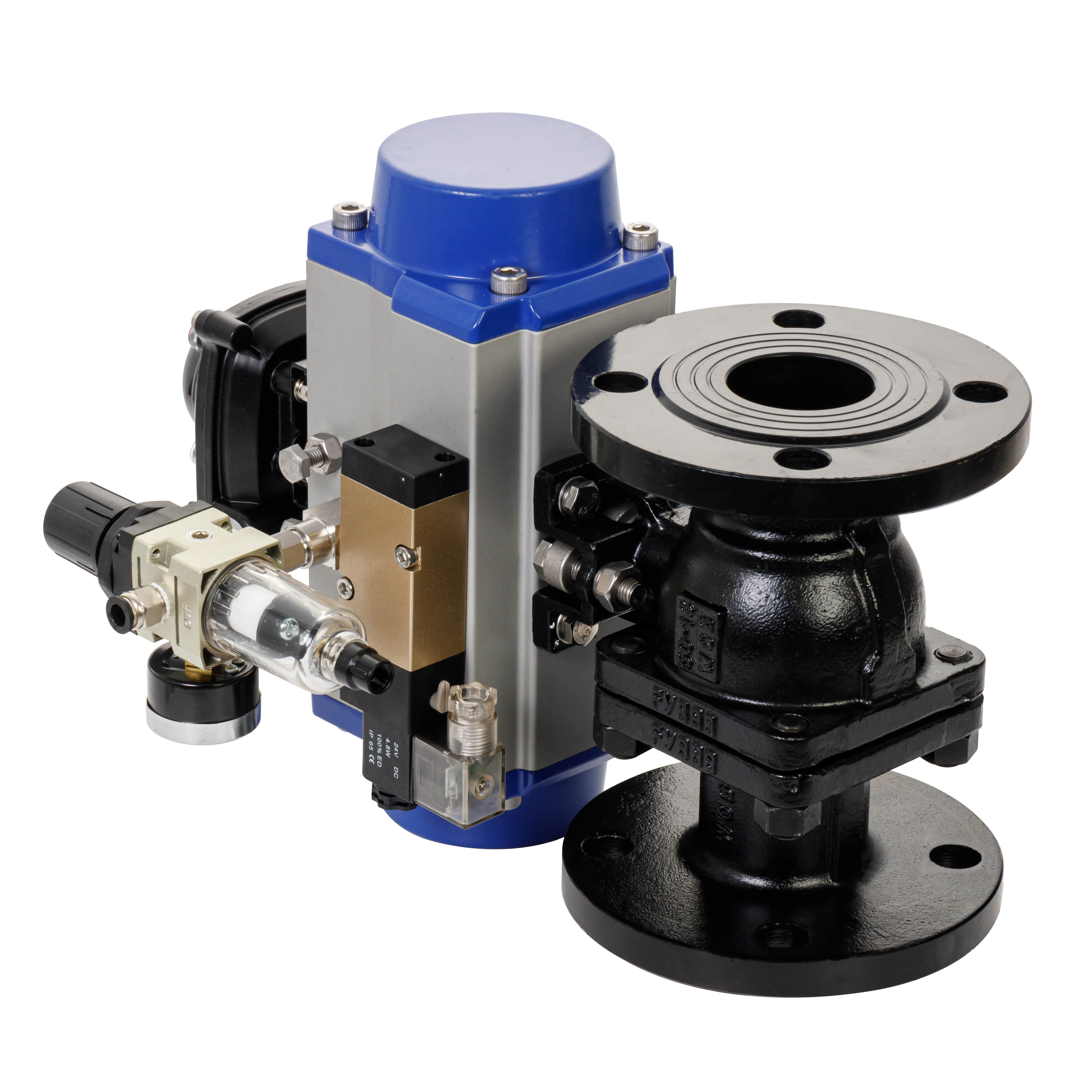

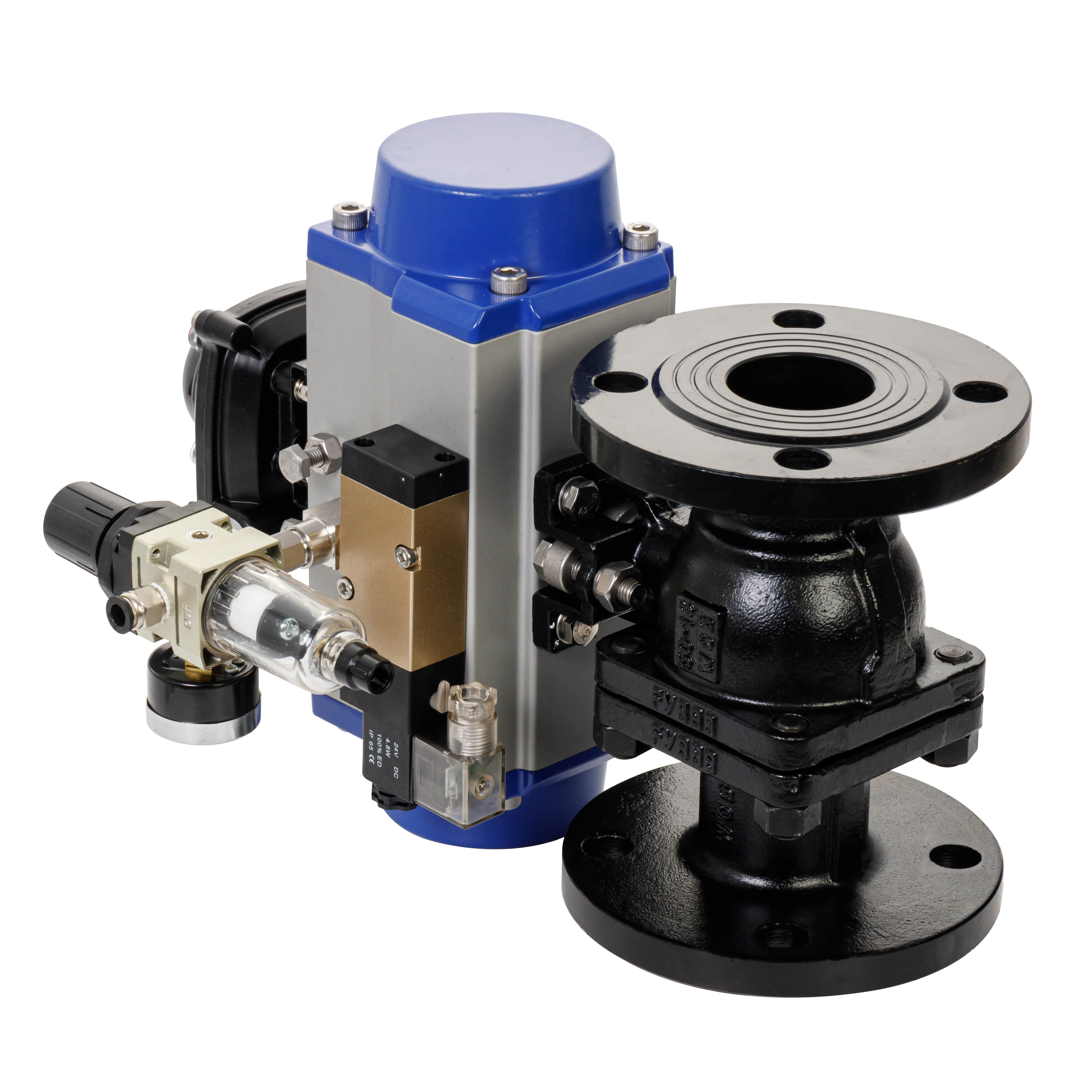

Mechanism of Pneumatic Ball Valves

A pneumatic ball valve consists of a spherical disc, or ball, with a hole through its center, which can be rotated to open or close the flow path. The valve operates through a pneumatic actuator, typically powered by compressed air. The actuator is connected to the ball valve and can move it from the closed position (where the hole is perpendicular to the flow) to the open position (where the hole is aligned with the flow).