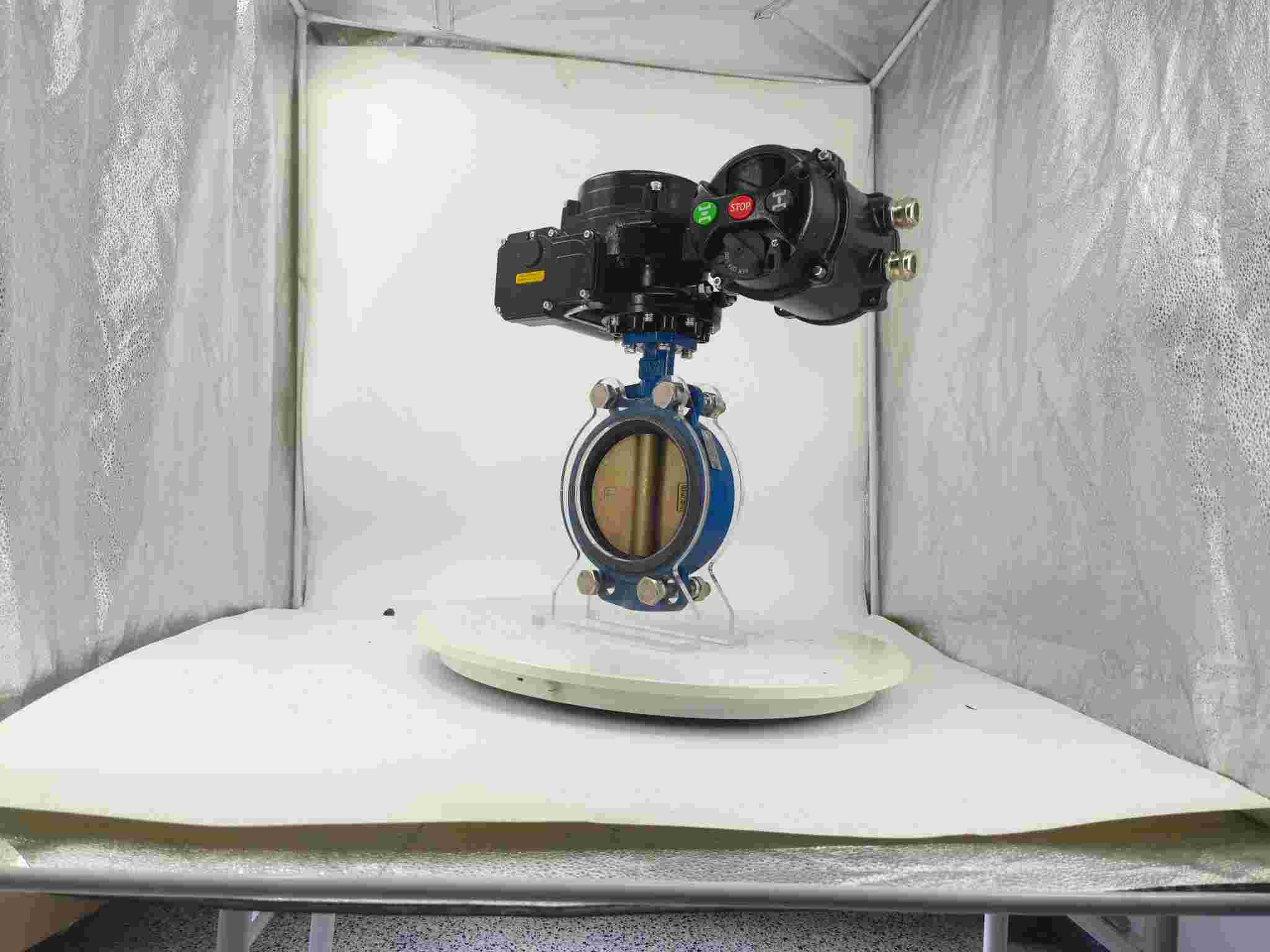

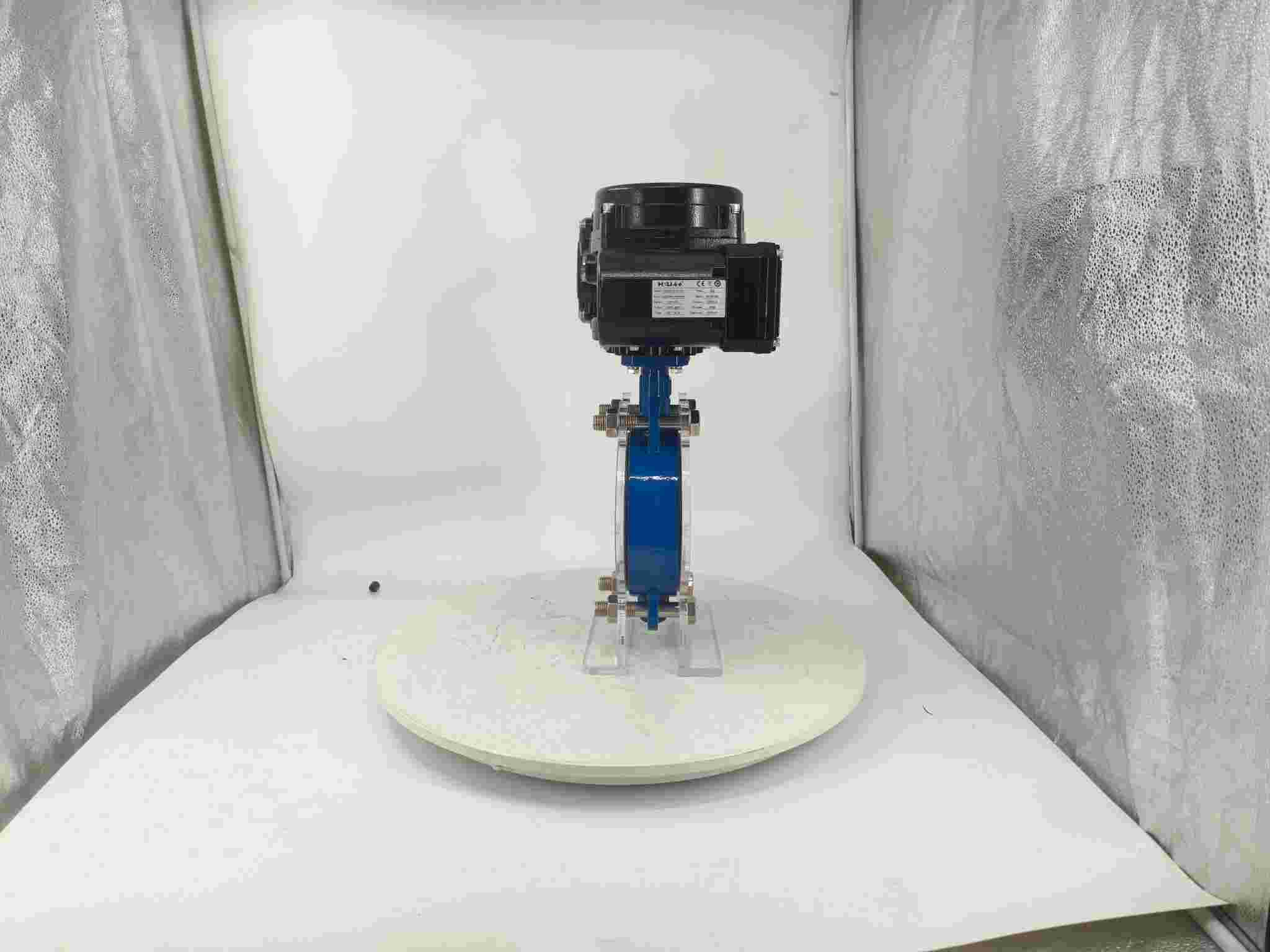

An Explosion-proof electric butterfly valve is a type of valve that combines the functionality of a butterfly valve with an electric actuator, designed specifically to operate in explosive environments. Butterfly valves are commonly used in pipelines to regulate the flow of fluids, gases, or slurries by means of a rotating disk, which controls the flow path. When combined with an electric actuator, the valve can be opened or closed remotely, providing greater control over the system.

Th "explosion-proof" feature refers to the valve’s ability to prevent the ignition of potentially explosive gases or materials. The electric actuator is housed in a protective enclosure that is designed to withstand external impacts and prevent any sparks or heat from escaping that could ignite an explosive atmosphere. This makes explosion-proof electric butterfly valves ideal for environments classified as hazardous, such as petrochemical plants, oil refineries, or any facility dealing with volatile chemicals.

e In industrial applications, safety is paramount, especially when dealing with potentially hazardous environments that involve flammable gases, vapors, or other combustible materials. An essential component to ensure safe operations in these settings is the Explosion-proof Electric Butterfly Valve. This specialized valve plays a crucial role in controlling the flow of fluids or gases while preventing the risk of explosion due to the ignition of hazardous substances. In this article, we explore the features, importance, and applications of explosion-proof electric butterfly valves in various industries.

What is an Explosion-proof Electric Butterfly Valve?